SafePilot Navigation Aid

SafePilot represents a new generation of navigation and piloting software, designed by a team of software programmers and working Pilots from around the world.

The result is intuitive Portable Piloting Unit (PPU) software, with touch screen technology, for fast interaction and reaction, built on an intelligent kernel for handling multi-layered charts.

A new intelligent chart structure enables instant zooming and a faster response than other navigational software is capable of.

SafePilot limits the information displayed to that of real value, offering optimum support to the Pilot at each phase of operation. It is also designed with a core that allows for expansion options for dedicated applications, such as docking, lock, river or offshore operations. Likewise, the system can be integrated with shore based systems, live data and personnel add-ons.

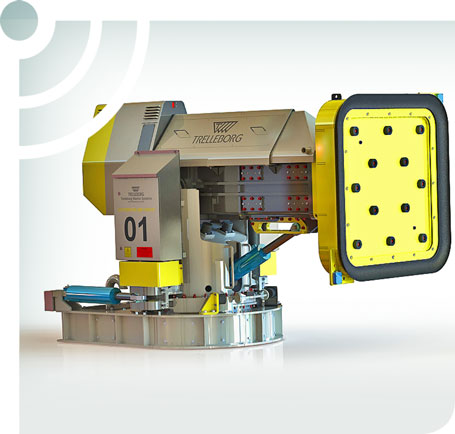

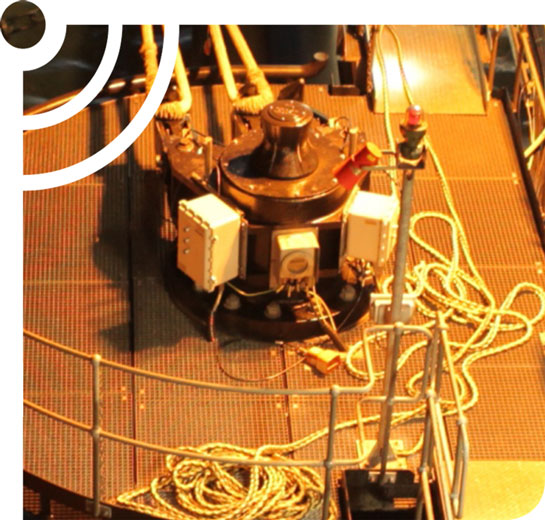

Challenge: A bespoke piloting system for longest pilotage route on US East Coast

Smart solution: A navigation sensor, used in paired units with one continuously charging, to accommodate the scale of the pilotage route, fully integrated with the port system and PPUs supplied: the “Chesapeake Class” CAT XT.

Outcome: Continuous operation along nearly 200 miles of waters, a capability that is completely unique to Trelleborg’s CAT XT product.

Docking Aid Systems (DAS)

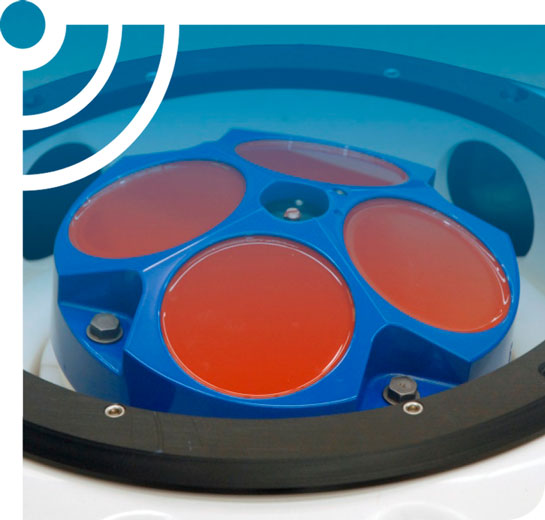

The SmartDock® provides vital information such as distance, angle and speed of approach to pilots and jetty operators, ensuring the vessel is safely docked and significantly reducing the risk of damage from a collision between ship and jetty. The typical system consists of two laser sensors, a controller, central PC and several data display options that the pilot and master can use to monitor and adjust approach.

SmartDock® improves situational awareness and enables operators to take corrective action should the approach profile exceed the limits. The lasers measure and update data second-by-second to build a ‘picture’ of the vessel’s approach. Information can be displayed in many ways.

A PC in the jetty control room logs the data and provides a graphical representation of the entire process. Vessel details are then stored in a database and can be quickly retrieved in preparation for future docking.

Meteorological Monitoring Systems

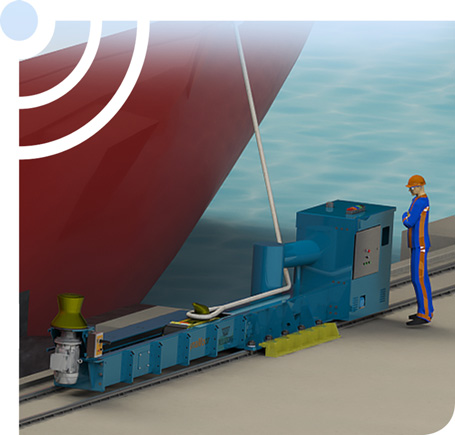

Real-time meteorological data and trends assist operators in maximizing their berth’s operating window by providing weather information to the staff at the berth, at the operations center, or on board the vessel.

Trelleborg’s Meteorological Monitoring Systems include sensors from leading instrument manufacturers and are typically compliant with WMO guidelines for accuracy and resolution. Instruments deployed in the marine environment are subject to harsh conditions and, as such, our experience in equipment selection and deployment techniques ensures rugged, reliable and maintainable systems suitable for the conditions.

These instruments are often integrated with oceanographic instruments to form MetOcean systems.

Oceanographic Environmental Monitoring Systems

Terminals are typically designed and operated with set limits for MetOcean conditions to ensure safety of the vessel and the terminal. Real-time MetOcean data and trends assist operators in maximizing their berth’s operating window by providing measurements at the berth. Tide, current and wave information can be provided to the staff at the berth, at the operations center, or to the vessel.

Trelleborg’s Oceanographic Monitoring Systems include sensors from leading instrument manufacturers, and all instruments deployed are suitably selected and developed to ensure appropriately rugged, reliable and maintainable performance.