Trust and reasurrance

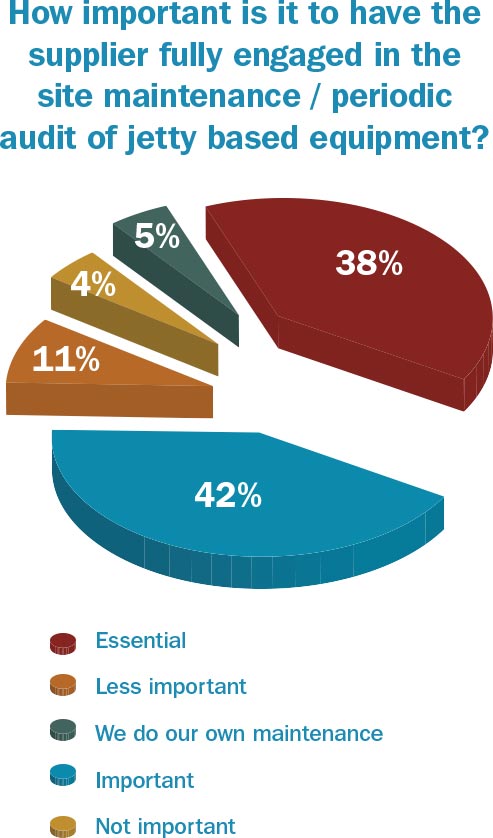

80% of those surveyed think it is essential / important to have suppliers involved in ongoing maintenance and service schedules

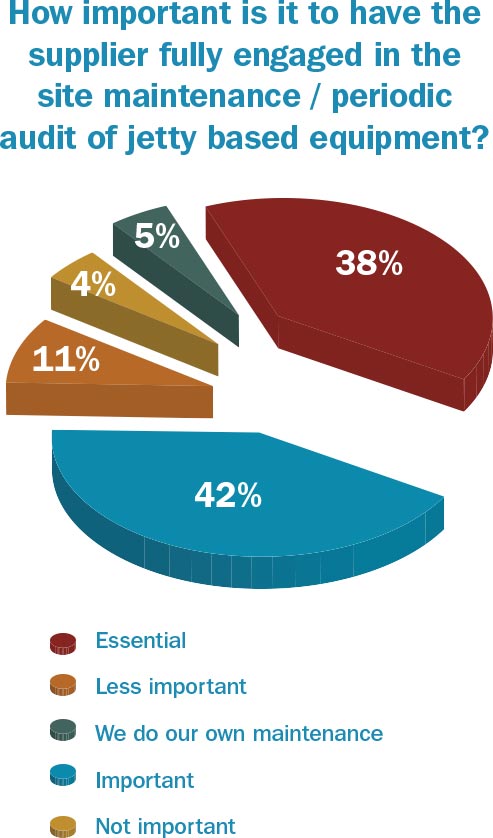

Over half of those surveyed believe that the user should be responsible for the regular inspection and maintenance of equipment. However, this can only be achieved by working closely with suppliers to define a maintenance schedule that takes into account the specific needs of the facility, as well as the best practice for individual equipment and components.

It’s critical that suppliers are involved in order to set the correct schedule and carry it out correctly.

Since port owners and operators have the impetus to ensure that robust maintenance schedules are put in place, to ease their operations over the long haul, we would suggest that they become more involved at the specification stage.

It might be ‘easier’ to hand over to contractors and consultants to deal with specification and implementation, but to improve business efficiency in the long term, facility owners and operators need to be involved so that the right, long term maintenance schedules can be put in place.

Conversely, the industry does seem to appreciate the importance of supplier expertise: respondents overwhelmingly want the supplier involved in ongoing maintenance and service schedules, with 80% feeling that this is essential or important.

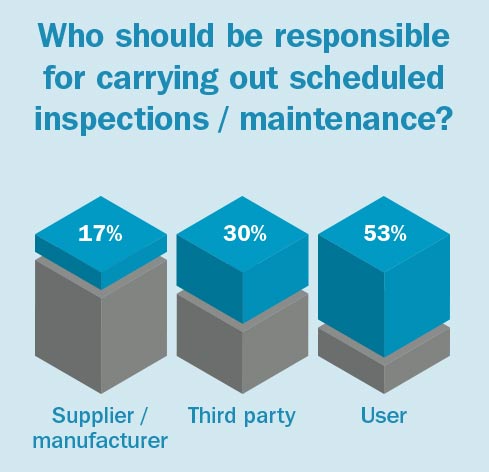

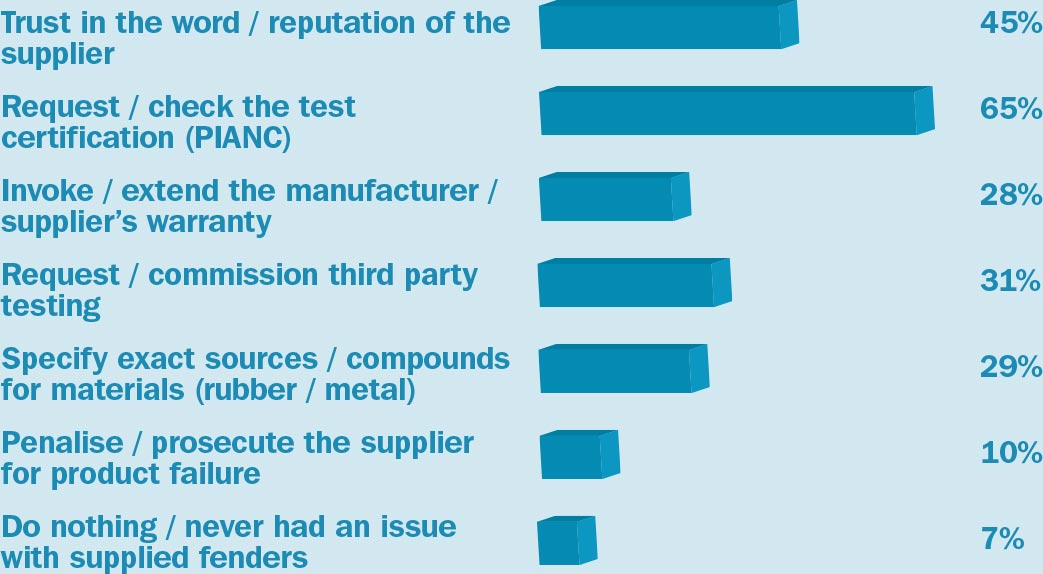

What steps do you take to ensure that marine fenders supplied to you are supplied as described?

These results show an extremely positive shift in the mindset of the market. Five years ago, nobody considered rubber compound specification, never mind implemented it. Now, almost 30% do so. Even more encouragingly, just over 30% also say they request or commission third party testing, highlighting a change in market thinking in both specifying quality and ensuring high standards set out in specifications are met.

PIANC does not have the resource, or indeed, the mandate to check ‘certification’ – and specifiers need to look for more robust ways to guarantee and test the quality of the products that they procure.

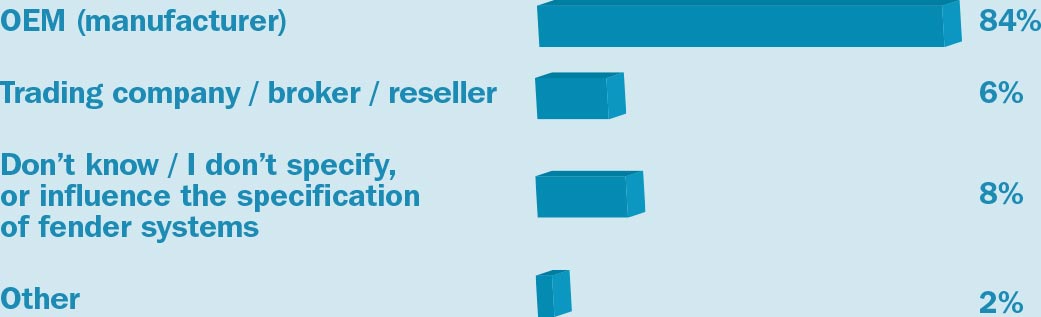

Which of the following would you trust to supply good quality, sold as described marine fenders?

84% would most trust an OEM to supply good quality, sold as described marine fenders.

This result is overwhelmingly positive. The vast majority now trust OEMs to supply good quality, sold as described fenders. This coincides with around 30% specifying material compounds, something that they are only able to do when buying from the manufacturer. It seems that over the past five years, the market thinking on fender procurement has undergone a sea change; the industry now values quality, and knows how to ensure they get it.

Although in 2010, over half of respondents felt that supplier expertise and support carried equal importance to the cost of their services, it seemed the industry talked the talk on the importance of the quality, but couldn’t truly claim to walk the walk.

This year, we’re taking the first steps. We’re beginning to see more respondents commissioning third party testing and implementing robust specifications. With this new emphasis on quality, when we look to the fifteenth Barometer Report in ten years’ time, we should hope to see this reflected in lower levels of downtime and an industry that is successfully handling the huge level of demand expected of it.